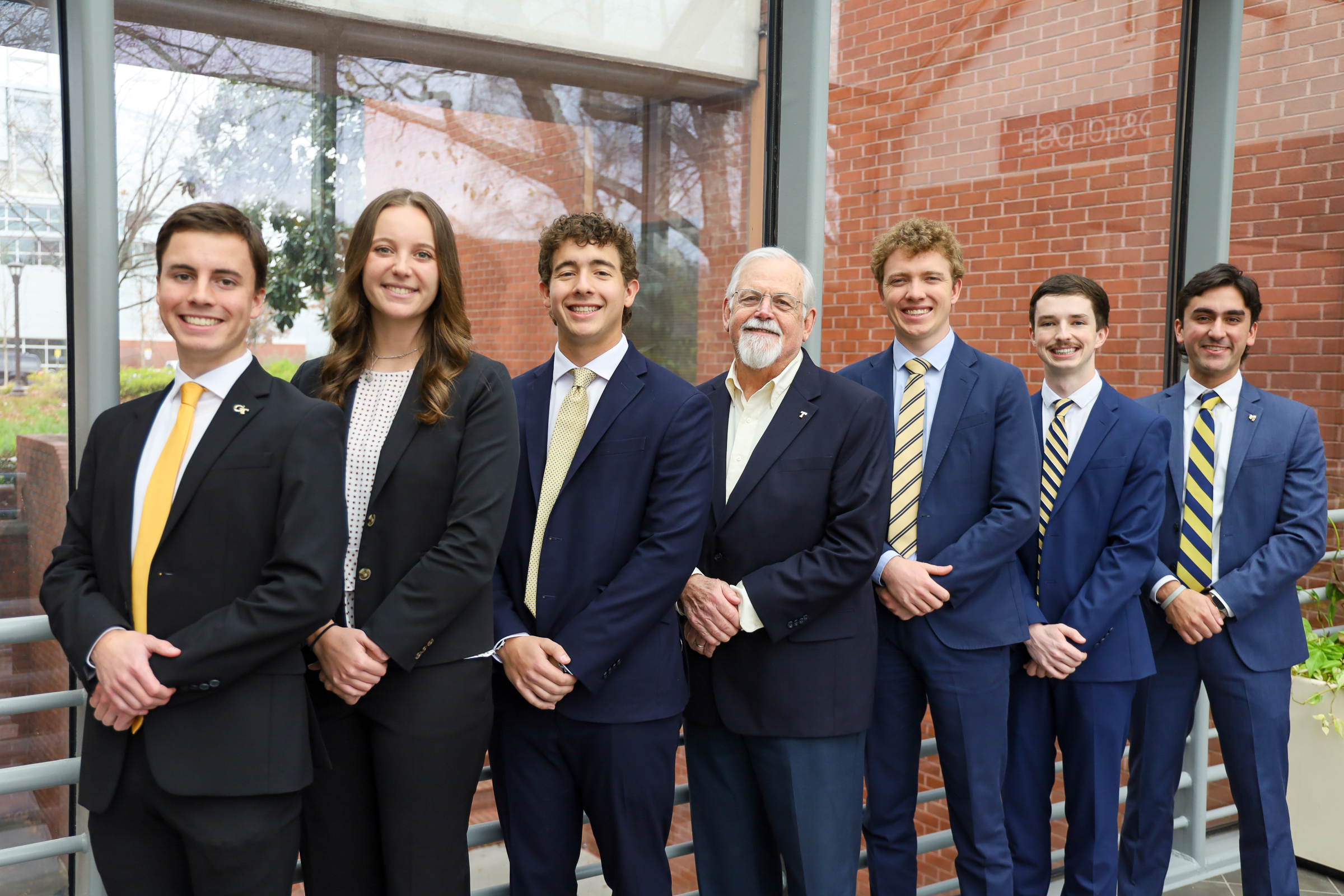

Of the 17 teams of undergraduates in the H. Milton Stewart School of Industrial & Systems Engineering (ISyE), the “Inventory Innovation: SyntheteX Marks the Spot” group has been named winner of the Fall 2025 Senior Design Competition. Students Aanan Biswas, Ethan Benater, Will Fox, Molly Hickman, Sristi Karamchandani, Guzide Melis Kargin, Rohin Shah, and Joshua Wen were selected for their project, working under the guidance of faculty advisor Alexander Shapiro.

A Growing Manufacturer Facing Volatile Demand

Synthetex is a Georgia-based manufacturer of geosynthetic fabric systems used for erosion control and infrastructure protection, with headquarters in Peachtree Corners and a production facility in Toccoa. With dozens of products and extensive customization, the organization operates in a complex manufacturing environment shaped by fluctuating construction demand. Historically, Synthetex relied on a make-to-order system, leading to sharp swings between overtime-heavy production and prolonged idle periods, delayed material procurement, and workforce challenges. These factors pushed average lead times beyond 12 weeks, sometimes as long as six months, putting customer deadlines at risk. To address these challenges, the winning senior design team developed a comprehensive plan to transition Synthetex to a proactive, hybrid production model.

Redesigning the System from the Ground Up

“When we analyzed the sales pipeline, we found that one in four orders experienced margin loss,” said Aanan Biswas during the team’s final presentation, noting that expediting materials and paying overtime eroded profitability, as one in ten orders was lost due to long lead times.

Rather than optimizing the constraints of the existing system, the team proposed a fundamental redesign.

The students’ solution centered on three integrated design changes: introducing strategic safety stock for raw materials so production can begin immediately, using idle-time production planning to turn unused capacity into semi-finished inventory, and redesigning the facility layout to accommodate higher inventory levels while meeting safety requirements. Together, these changes create a data-driven production planning framework that puts the right products on the right machines at the right time, reducing changeovers and avoiding stockouts.

Using Data to Make Measurable Impact

“One of the key ways that we're helping Synthetex derive value from this project is through its data,” said Rohin Shah. The team took their client’s siloed data sources and created a streamlined solution. “For example, if the client wanted to look at its material usage, they would have to hunt through dozens of files in SharePoint and extract all of that manually, before even being able to look at that data. With our automated solution, it’s structured, it's aggregated, it's tabulated, and easy to use and analyze. Ultimately, in the future state, every decision that Synthetex makes has the potential to be data-driven because of these automated data assets.”

The redesigned system is projected to cut average lead times by nearly 39% (from more than 12 weeks to under 7.5 weeks) while significantly reducing margin losses and lowering the rate of lost orders from one in ten to one in fourteen. Overall, the team estimates a 14% increase in profit in the first year alone, and Synthetex has already begun implementing the recommendations with an initial investment of approximately $7,000.

Client Praise for Insight, Dedication, and Impact

Rachel Wewengkang (IE 2023), Business Analyst at Synthetex and the team’s primary client contact, praised both the impact of the students’ work and the process behind it.

“Initially, the project was submitted with a focus on pricing optimization. However, after conducting lots of research, the team proposed a change in scope that proved to be far more valuable,” said Wewengkang. “Their solution would give us significant improvement in inventory management. Their second opportunity provides a pathway to utilize idle resources for bulk roll production, supported by a model that prioritizes production decisions with data-driven evidence.”

Wewengkang also highlighted the students’ persistence and initiative throughout the project, noting how they not have access to all the data they ideally needed. Nonetheless, they impressed the client by working with limited information, gathering new data where possible, and making well-reasoned assumptions to deliver meaningful results.

A Senior Design Experience That Defines ISyE

All fourth-year students in ISyE culminate their undergraduate educational experience with the Senior Design course to provide firsthand experience in solving real world problems in a team environment. Groups work with leading businesses and organizations to take engineering principles learned in the classroom and apply them to create solutions. The other finalist in this semester’s competition, Perfecting Pin Placement (Green Jackets), worked with a top golf course to help their client make more informed and consistent daily pin-placement decisions for their tournament.

Faculty leaders say the project exemplifies the purpose and impact of ISyE’s senior design program.

“I couldn’t be prouder of what our students accomplish in senior design,” said Dima Nazzal, ISyE Associate Chair for Academic Administration.

“These projects represent not just technical excellence, but a journey filled with challenges and perseverance. Our alumni often tell us that senior design was the most impactful experience of their education, and it’s because of this exact process of learning to push through uncertainty and ambiguity to create impact.”

The course is intentionally structured to mirror real-world engineering practice, explained Gamze Tokol-Goldsman, ISyE Senior Lecturer and Senior Design Co-Coordinator. Tokol-Goldsman also works alongside ISyE Senior Lecturer and Senior Design Co-Coordinator Laura Li, to provide students with guidance during the semester. Li added that the open-ended nature of the experience is often the greatest challenge, and the greatest source of growth.

“It is a journey; students must learn how to formulate a problem and analyze that problem, and they are doing everything on their own. In the end, we’re always pleasantly surprised by how much they’ve learned throughout the process. That’s the most enjoyable part – to see how much progress the students have been making.”

Preparing Engineers to Lead Through Ambiguity

For this semester’s winning Senior Design team, the recognition marks the culmination of months of analysis, site visits, modeling, and iteration, but also the beginning of their professional impact beyond the classroom.

By delivering a solution that Synthetex is already putting into practice, the students demonstrated not only technical mastery, but the ability to navigate ambiguity, collaborate with industry partners, and design systems that create lasting value—hallmarks of the ISyE senior design experience.